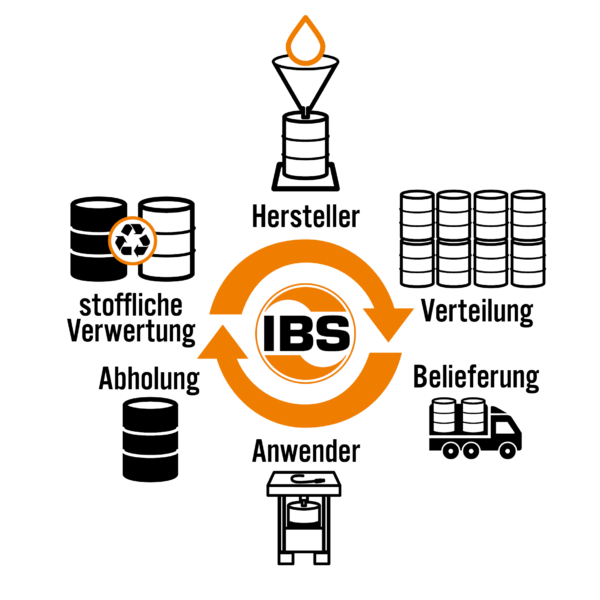

IBS cycle: eco-efficient and circular economy

IBS parts cleaning equipment and special cleaners impress with their excellent eco-efficiency and comply in all respects with the law on the promotion of the circular economy.

Recycling instead of disposal

The use of an IBS parts cleaning device avoids the generation of unnecessary waste. The cleaning agent is circulated until it is saturated. In the IBS take-back system, the used cleaner is sent for recycling.

Barrel change service

As soon as the cleaning agent in the drum is saturated, it can be replaced with a new drum of fresh IBS special cleaner. In many countries, IBS offers the so-called barrel exchange service. As part of a delivery, the IBS service driver replaces the old drum with a new IBS special cleaner. The take-back is free of charge and the customer receives the legally required proof of disposal.

Recycling and waste treatment plant

The drum with the used cold cleaner is taken to the company’s own recycling and waste treatment plant in Gau-Bickelheim, Germany, and reprocessed. The purifier is physically pre-purified: filtered, centrifuged and then distilled and refined. This means that almost 100 % of clean IBS cold cleaner can be returned to the economic cycle. Even the oil sludge previously filtered out is used to generate energy, for example in incineration.

100% recycling

IBS is a pioneer in the circular economy of parts cleaning. The recycling rate of the IBS cold cleaner is almost 100 %. IBS thus fulfills the requirements of the law to promote the circular economy and actively contributes to environmental protection.

IBS parts cleaning is the environmentally friendly and sustainable solution for parts cleaning.