Water-based cleaning agents for industry: efficient and environmentally friendly

Aqueous cleaners are one of the most commonly used types of cleaning agents in the industry. They are usually highly concentrated and are therefore diluted with water before they are used. This saves costs and transportation volumes.

Composition of aqueous cleaners

Aqueous cleaners consist of three main components:

- Surfactants: Surfactants are surface-active substances that enable good wetting and emulsification of dirt. They are the most important components of aqueous cleaners.

- Builder: Builders are inorganic or organic builders that regulate the pH value of the cleaner and improve cleaning performance.

- Additives: Additives can give the cleaner additional properties, e.g. corrosion protection, beading and shine effect, anti-slip effect, etc..

Types of aqueous cleaners

Types of aqueous cleaners

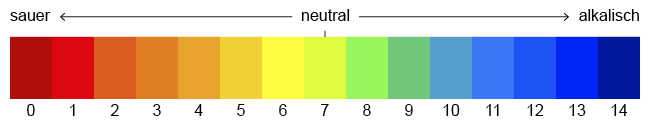

Aqueous cleaners are divided into three categories according to their pH value:

- Acidic cleaners: Acidic cleaners have a pH value below 7 and are often used to remove limescale, rust and other mineral deposits.

- Neutral cleaners: Neutral cleaners have a pH value of 7 and are suitable for cleaning sensitive surfaces, e.g. plastic, glass and stainless steel.

- Alkaline cleaners: Alkaline cleaners have a pH value above 7 and are often used to remove grease, oil and other organic contaminants.

Categories

Aqueous cleaners are also divided into different categories according to their application:

Aqueous cleaners are also divided into different categories according to their application:

- Spray cleaners (high-pressure and workshop cleaners)

- Immersion cleaner (ultrasonic cleaner)

- Manual cleaners (machine cleaners/spray cleaning, wiping method)

Advantages

Aqueous cleaners offer a number of advantages:

- Easily biodegradable (according to OECD criteria) and environmentally friendly

- Generally more cost-effective than solvent-based cleaners

- available in a variety of formulations suitable for different applications

- The water-based cleaners from IBS Scherer are demulsifying (the cleaning solution immediately separates oils and greases from the components and allows them to float on the surface), making them suitable for the oil separator (longer service life) and have a tested separator friendliness. They meet the requirements of ÖNORM B 5104, B 5105 and B 5106 with regard to waste water.